![]()

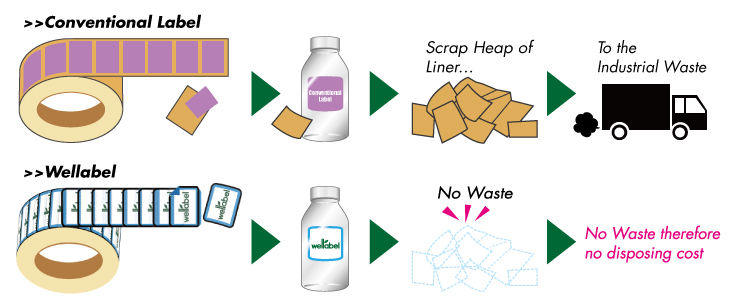

For conventional label,

the Liner becomes waste after peeling

and this waste is useless.

▶ No waste, No dispose!

There is no liner therefore no waste. Enable to reduce the cost by eliminating the liner and disposing cost.

▶ Reconsider the material and production process to fulfill the label cost reduction!

Since 1934 when Facestock + adhesive + Liner as "Cell Label" has been invented, we have been using the labelafter pealing off the liner without any doubt. This mean is that we have been disposing the liner as waste. With "Wellabel®" no trouble disposing and creating the Industrial Waste.

Disposing cost for the waste liner will cost JPY7,000.-/ton(our company survey). With "Wellabel®", the cost will be save by not creating the waste to eliminate the disposing cost.

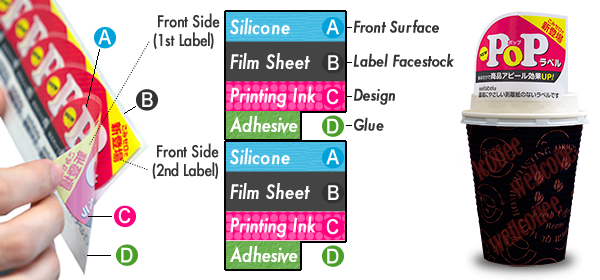

"Wellabel®" uses material such as OPP and PET Film as facestock and coat adhesive and silicone as separator directly. For example POP Label as sales promotion "Wellabel®" can coat the adhesive to the section only need it as idealistic adhesive reduction. Such as POP Label, you only need to coat the adhesive where you need to coat.

![]()

Save the Space,

Labor & Transportation Cost

by "Wellabel®".

▶ 1 "Wellabel®" web is equivalent to 2 conventional label web with same in the number of labels.

▶ That means followings

Removing the liner from conventional label, twice the number of labels will be able to roll up in one "Wellabel®" web.

Reduce the storage space and trouble for web changover will be reduce to 1/2.

Smaller web volume can reduce packaging and transportation cost to 1/2 per label.

![]()

Linerless, free shape "Wellabel®" contributes to reduce

label cost and the burden to our environment.

Economical & Ecological label.

▶ Operator and Environment-Friendly Specification.

▶ Non-Harmful Flexographic Ink is use.

▶ "Wellabel®" can correspond to the ○, △ and trapezoid as various types of shapes.

Various types of shape according to the usage and purpose.

Various types of printing machines and inks can be used to produce "Wellabel®". We recommend flexographic ink for further ecological contribution as in "Wellabel®".*

* "Wellabel®" has received high assessment for eco-friendly at Label Expo held in Europe in 2013.

Any shapes (circle, trapezoid, triangle, elliptical) of labels with shingling label structure, that the conventional linerless label technology cannot afford, can be produced according to the customer's needs regardless the number of labels by the "Wellabel®" manufacturing machine.

![]()

By dedicated Applicator "LL-100R"

there are no need for

manual application.

By implementing the dedicated Labeling System it made possible for quality stability and product manufacturing with less

number of operators.

▶ Double amount of the label into 1 label web to reduce the trouble for changing the label web.

▶ Implementing the dedicated Labeling System, manual process will be systemize.

"Linerless Label" which constructed by shingling the each Label to the Roll Shape. It can roll the double amount to the 1 label web and trouble to change the web will be 1/2. We have developed the dedicated labeling system to use characteristic of the "Wellabel®"'s effectively and at same time to have the efficient production.

It made possible to manufacture the "Wellabel®" by dedicated Labeling System (Label Convertor & Automatic Applicator) in-house efficiently. To systemize the manual into automatic operation to eliminate the quality deviation and to reduce the operators.